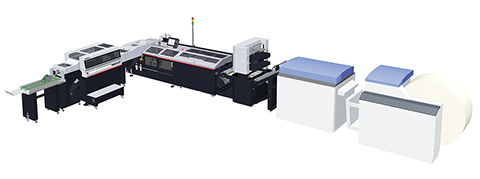

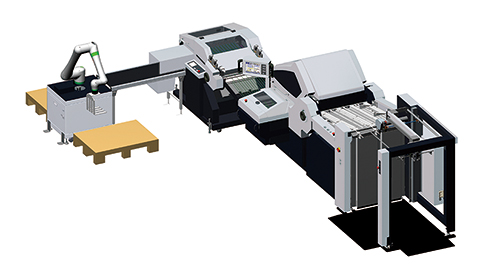

iCE STITCHLINER MarkⅤ NEW

The iCE STITCHLINER Mark V is our roll-to-booklet saddlestitcher that achieves high productivity with a maximum production speed of 6,000 booklets per hour. Sheets are individually scored and plow-folded before stitching for sharp spines and tight folds.

In collaboration with SCREEN Holdings Co., Ltd.

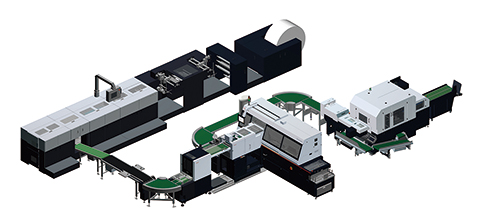

Inline SmartStacker & Book Production

This is our inline book production solution that processes B2 printed sheet into perfect bound books. An AGV brings pallets loaded with B2 printed sheets to our SmartStacker infeed section for automated loading. The SmartStacker is equipped with inspection devices by DAC ENGINEERING for high-level quality control.

In collaboration with FUJIFILM Global Graphic Systems CO., Ltd. and DAC ENGINEERING CO.,LTD.

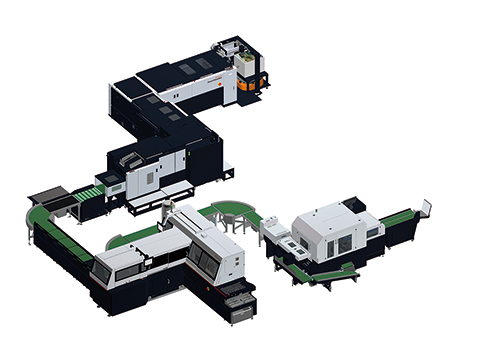

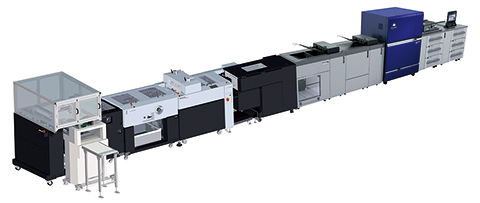

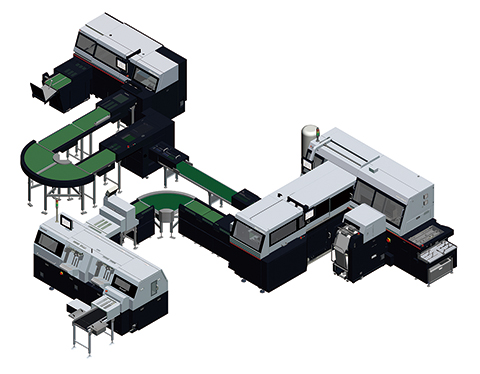

Inline Cut Sheet Printer & Book Production NEW

This inline cut sheet press solution enables variable book production with no operator makereadies and automatic changeovers. Two presses (one for book blocks and one for cover sheets) are connected inline, with the cover sheets being printed based on book-block contents and then automatically fed into a binder. Book blocks are processed with our SmartSlitter and then fed into the binder with a robotic arm.

In collaboration with Ricoh Japan Co., Ltd.

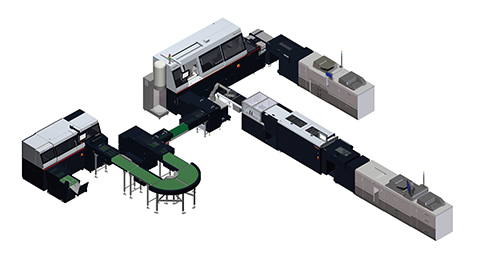

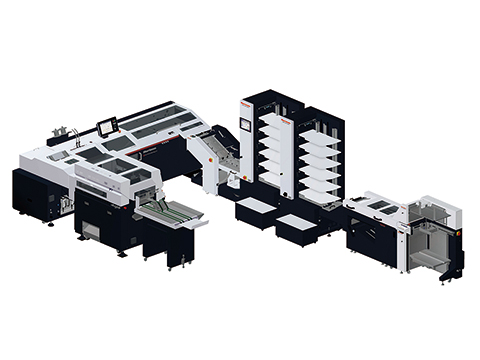

Signature Gatherer Inline Book Production System NEW

This solution is designed to produce books from offset-printed signatures and features our gatherer, book block feeder, 4-clamp perfect binder, and three-side trimmer all connected inline. Palletized signatures will be transported by an AGV from the Folder to Palletizing Robot System.

In collaboration with RYOBI MHI Graphic Technology Ltd.

Folder with Palletizing Robot

This B1-to-signature production system eliminates all manual labor involved with transportation, loading, and palletizing by utilizing an AGV and robotic arm.

In collaboration with RYOBI MHI Graphic Technology Ltd.

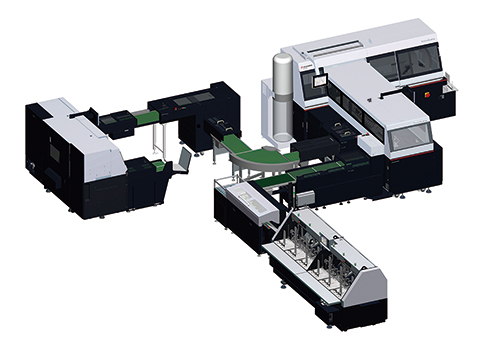

Plow Fold Book Production System NEW

This roll-to-book solution allows for book-of-one production at a high production speed of up to 800 books per hour. A plow-fold book block system is integrated inline with our book block feeder, perfect binder, and variable trimmer to allow for roll-to-book production in one pass.

In collaboration with Miyakoshi Printing Machinery, Co., Ltd.

Inline Cut Sheet Press & Cut Sheet Processing

This inline print-to-finish solution with our SmartSlitter allows for touch-free production of greeting cards, business cards, cover sheets, and more. Reduce labor costs and turnaround times by performing common applications such as creasing, perforating, slitting, and trimming inline without the need for manual processing on multiple machines.

*The exhibited products may be changed.

In collaboration with Canon Marketing Japan Inc.

Inline Cut Sheet Press & Die Cutting

This inline print-to-finish solution features our die-cutter and a robotic-hand that allow for touch-free production of greeting cards, business cards, cover sheets, and more. Reduce labor costs and turnaround times by performing common applications such as creasing, perforating, slitting, and trimming inline without the need for manual processing on multiple machines.

In collaboration with KONICA MINOLTA, INC. and DAC ENGINEERING CO.,LTD.

Robot Arm Book Production

This print-to-book production solution features inline robotic feeding to allow for continuous production. Book blocks are printed, fed into our one-clamp perfect binder with a robotic arm, and then finished with our three-side trimmer.

In collaboration with RISO KAGAKU CORPORATION

iCE STITCHLINER MarkⅣ NEW

The iCE STITCHLINER MarkⅣ is our sheet-to-booklet saddlestitcher that features further improved automation and binding quality. This user-friendly system provides increased efficiency and stable binding quality to meet various market needs.

Inline Pocket Folder System NEW

This inline system features our rotary-die cutter, gluing unit, and buckle folder to make pocket folders with environmentally friendly materials.

Case Bind Book Block Production System NEW

This inline solution allows for high-mix, low-volume case preparation from any type of book block by integrating our end sheet feeder, loose-sheet book block feeder, perfect binder, gauze applicator, and trimmer into one system.

Workflow Zone

① JSPIRITS Inc.

② Ricoh Japan Co., Ltd.

③ KONICA MINOLTA, INC

④ SCREEN Holdings Co., Ltd.

⑤ FUJIFILM Global Graphic Systems CO., Ltd.

⑥ RYOBI MHI Graphic Technology Ltd.

⑦ Heidelberg Japan K.K.

⑧ iCE LiNK by Horizon Inc.