Products Video

- Home

- Horizon Products

- Digital Finishing

- SmartSlitter

Product Brochure

Sheet Cutter and Creaser

SmartSlitter

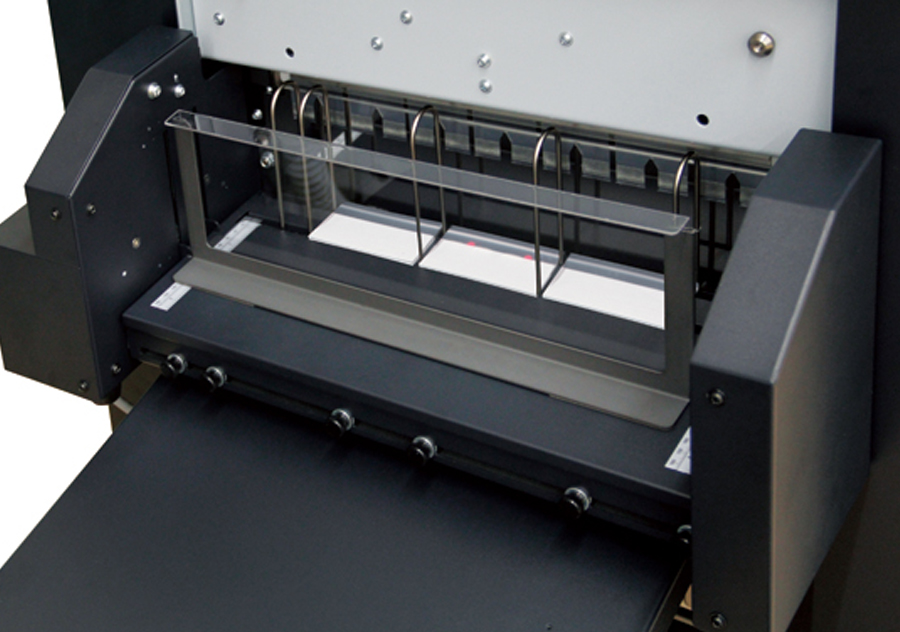

Sheet cutting, creasing, and perforating in one pass. A quality fi nishing process for digitally printed sheets.

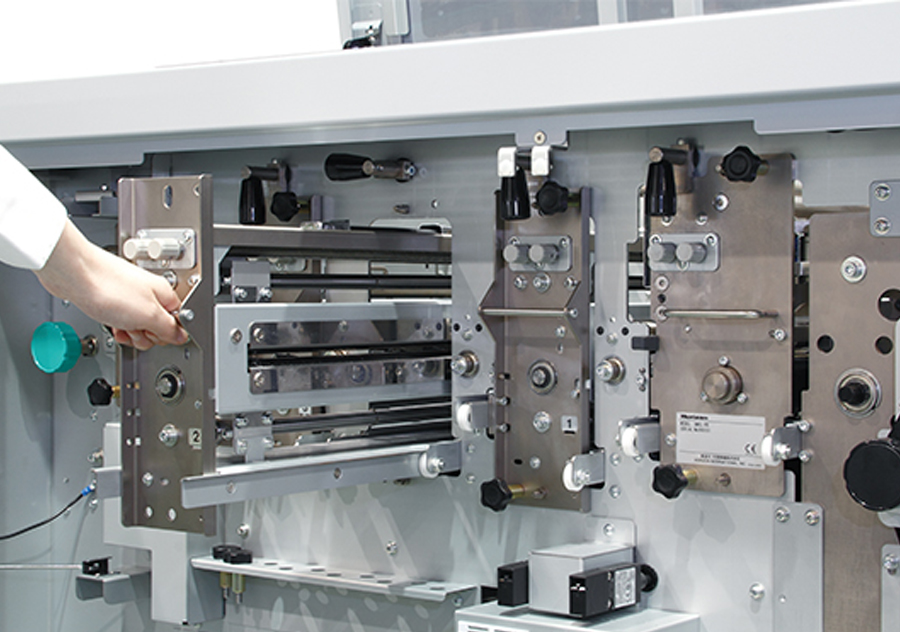

Creasing, Perforating, and Sheet Cutting in One Pass – The creasing, perforating and sheet cutting can be performed for various applications such as business cards, shop cards, invitation cards, greeting cards, laminated sheets, and covers for perfect binding.

Skip Perforation – The SMSL-PR optional perforation cassette enables skip perforation for various applications such as coupons, tickets and checks.

User Friendly Operation – New high resolution color touch screen display for easy and intuitive operation.

MANAGE YOUR BINDERY WITH HORIZON'S BINDERY CONTROL SYSTEM –The system can be enhanced with automated workflow from upstream to post-press with iCE LiNK, which uses cloud technology, Horizon's post-press management system.

Specifications

| Model | SMSL-100 |

|---|---|

| Sheet Feeding System | Air Suction Feed Belt |

| Sheet Size | Width x Length Max. 370 x 670 mmor 14.565” x 26.375” Min. 200 x 200 mmor 7.875” x 7.875 |

| Finished Sheet Size | Width x Length Max. 370 x 670 mmor 14.565” x 26.375” Min. 48 x 50 mmor 1.890” x 1.970” |

| Sheet Weight Range | Normal Paper: 81.4 to 350 gsm Coated Paper: 105 to 350 gsm <SMSL-PR Rotary Perforate Cassette / SMSL-MPR Manual Perforation Cassette / PRF-36 Impact Perforation Unit> Normal Paper: 81.4 to 209 gsm Coated Paper: 128 to 256 gsm |

| Feeder Stack Height | 150 mmor 5.9” |

| Number of Impact Creasing Lines | 20 crease lines |

| Production Speed | 54 sheets per minute (A4 short-edge feeding, two cuts, one crease line) 48 sheets per minute (JIS B3 short-edge feeding, two cuts, one crease line) |