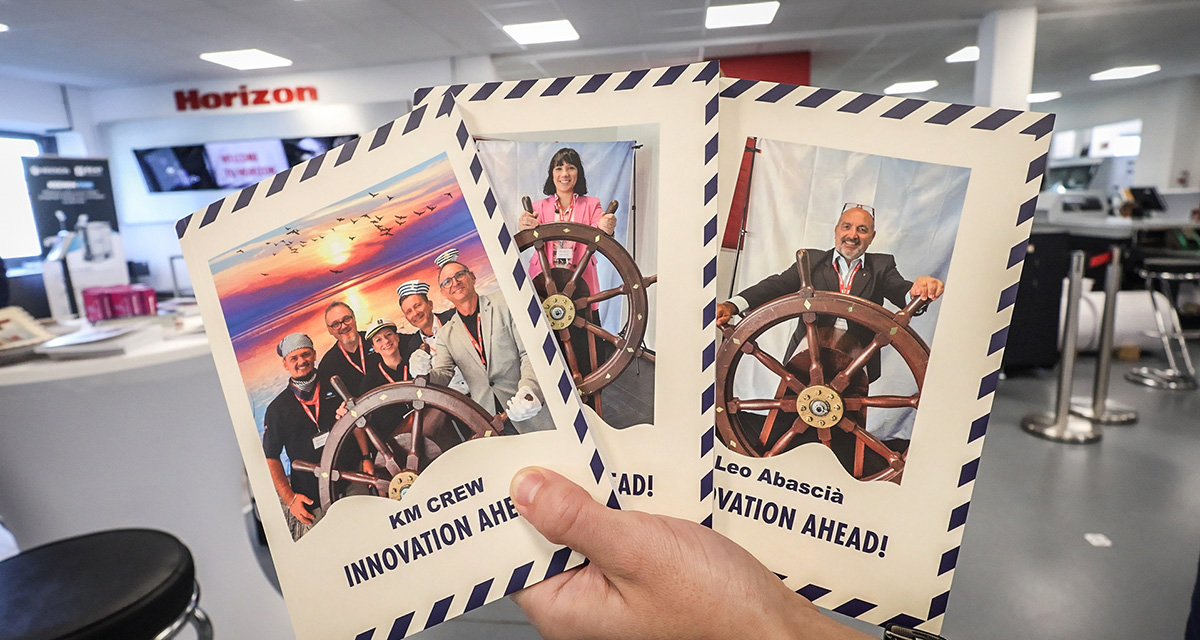

For two days from September 24-25, 2025, Horizon GmbH hosted their largest Finishing First event yet, with 200 customers from 23 countries and over 30 industry partner companies.

Thank you to everyone who attended and helped make Finishing First possible!

We hope it was just as productive and exciting for everyone as it was for us.

Highlight Videos

Here are a few of the highlights for those of you who couldn’t make it.

Click to Jump to Desired Section

- iCE STITCHLINER MARK V with Hunkeler & Palamides

- Roll-Fed Smart Folding System with Tecnau

- Roll-to-Book Smart Binding System with our BBS-56

- Die-Cut-to-Fold Direct Mail System (RD-N4055+AFV-56S)

iCE STITCHLINER MARK V with Hunkeler & Palamides

*Additional partners include Canon, Konica Minolta, and Screen for printing

At Horizon Finishing First 2025 our iCE STITCHLINER Mark V was integrated with Hunkeler’s Generation 8 roll processing technology upstream, and Palamides’ new stacking & banding unit downstream for roll-to-banded-booklet production in a single pass.

The latest Mark V interface technology allows for seamless integration and machine communication with upstream and downstream 3rd party devices. This translates to no-touch job changeovers for efficient booklet production, even for booklets with variable page count and finish size.

Roll-Fed Smart Folding System with Tecnau

*Additional partners include Ricoh for printing, and UPM for paper

Take folding automation to the next level with this no-touch, continuous feed folding system that seamlessly integrates TECNAU’s latest guillotine cutting technology and our AFV-56S series cross folder.

At Horizon Finishing First 2025 this system produced both 3-panel and 4-panel fold applications 2-up with automatic, no-touch changeovers in between jobs.

Roll to Book Smart Binding System with our BBS-56

*Additional partners include Canon and Screen for printing, and Crown van Gelder for paper

Produce short- to medium-run book jobs, even those with different page counts and finish sizes, efficiently in a single pass with our BBS-56 Integrated Smart Binding System. Our continuous feed book block processor, the BBS-56, utilizes plow fold and starwheel stacking technology to produce glue-tac book blocks for a BQ-500/HT-1000V Smart Binding System.

At Horizon Finishing First 2025, this system produced books from rolls printed by Canon and Screen, containing book jobs of variable sheet count and finished sizes on each roll. Paper rolls were supplied by Crown van Gelder.

Die Cut to Fold Direct Mail System

*Collaboration with Konica Minolta for printing, and Kocher + Beck for the dies

This system integrates our rotary die cutter RD-N4055DM inline with our latest buckle folder AFV-566SF to efficiently produce value-added applications for direct mailing.

The system accomplishes die cutting, perforating, creasing, embossing, kiss cutting and folding in a single pass, allowing customers to achieve high quality direct mail applications with fewer operator touchpoints.