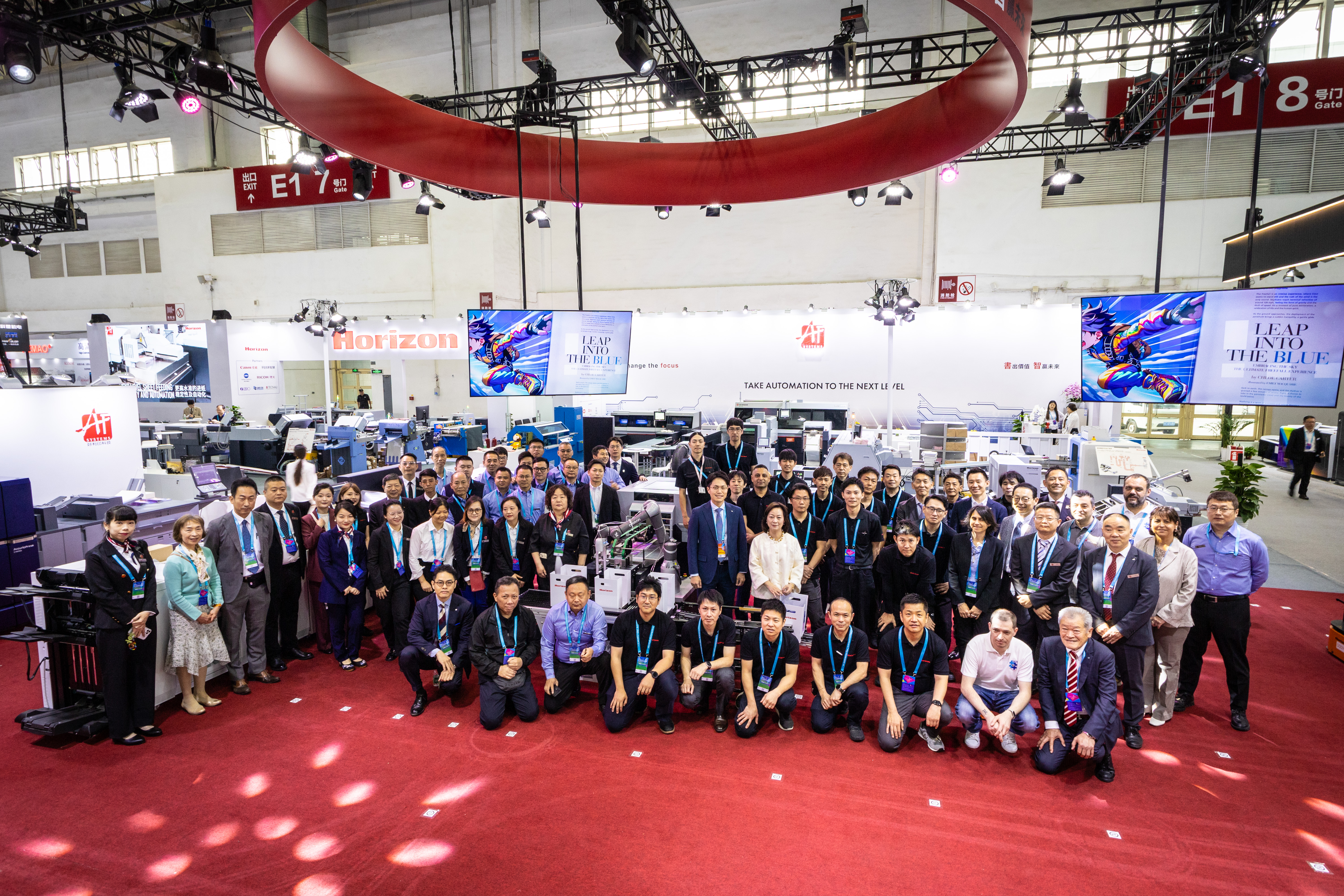

From May 15–19, 2025, Horizon, together with our regional partner Advanced Finishing Systems, participated in the 11th Beijing International Printing Technology Exhibition (China Print 2025), held at the China International Exhibition Center (Shunyi Hall). Under the theme “Change the Focus, Create Value” we delivered an impactful showcase of next-generation postpress technologies.

Visitors from across China and beyond experienced firsthand how Horizon is driving a shift toward automation, efficiency, and value creation in the print finishing world. With live demonstrations, integrated systems, and collaborative solutions on display, the event offered a dynamic platform for meaningful exchange with customers, partners, and industry professionals.

Systems Lineup - Table of Contents

Click to Jump to Desired Section

-

・AGV-ASSISTED SADDLE STITCHING SYSTEM (CANON / KONICA MINOLTA)

・SEWN BOOK BLOCK CASE BIND PREPARATION SYSTEM (SMYTH)

・ROLL-FED SMART BINDING & PACKAGING SYSTEM (TECNAU)

・ROBOTIC ARM POD BOOK SYSTEM (RISO)

・ICE STITCHLINER MARK IV

・ICE STITCHER SPF-2000 & STANDALONES

-

・INLINE CUT SHEET PRESS & ROTARY DIE CUTTING SYSTEM (KONICA MINOLTA BOOTH)

・INLINE CUT SHEET PRESS & PROCESSING SYSTEM(FFBI BOOTH)

AGV-ASSISTED SADDLE STITCHING SYSTEM

*Collaboration with Canon and Konica Minolta

Experience lights out booklet production with this futuristic system that features two AGV and two cut sheet presses (from Canon and Konica Minolta) seamlessly integrated together with our latest digital saddle stitching system: the iCE STITCHLINER Mark V. Printed cut-sheets are transported directly from the presses to the high speed sheet feeder of the Mark V via our specially designed paper transport AGV.

SEWN BOOK BLOCK CASE BIND PREPARATION SYSTEM

*Collaboration with Smyth

This system features Horizon's Case Bind Book Block Preparation System integrated inline with SMYTH's DX-E book block sewing unit, enabling a fully automated workflow that performs book block sewing, end sheet tipping, and gauze application in a single pass. This seamless integration streamlines the case binding preparation process, improving efficiency and reducing manual handling.

ROLL-FED SMART BINDING & PACKAGING SYSTEM

*Collaboration with Tecnau

This system handles the entire book production process from web processing—with Tecnau’s Revolution 50 Series Unwinder U50 and the new Cutter C7—to perfect binding and package wrapping, all in a single pass. Our 9-clamp perfect binder SB-09RF and 3-knife trimmer HT-1000R are equipped with sleek new covers that enhance safety and user-friendliness.

ROBOTIC ARM POD BOOK SYSTEM

*Collaboration with Riso

The Robotic Arm POD Book System eliminates manual touchpoints by using a robotic arm combined with inline binding and trimming. Printed book blocks from a Riso printer are delivered directly to a jogging station. From there, a robotic arm picks up the book blocks and feeds them into our brand-new iCE BINDER BQ-300 single-clamp perfect binder. Once bound, the books are transported by conveyor to the iCE TRIMMER HT-300 variable 3-way trimmer for precise finishing—all within a seamless, automated workflow.

ICE STITCHLINER MARK IV

Our latest sheet-fed saddle stitching system, the iCE STITCHLINER Mark IV, delivers a wide range of booklet applications at speeds of up to 6,000 cycles per hour. For China Print 2025, the layout will include both VAC collating towers and the HOF-400 offline sheer feeder to efficiently manage workflows from both offset and digital printing.

ICE STITCHER SPF-2000 & STANDALONES

See our newest booklet making system, the iCE STITCHER SPF-2000, and other popular standalones like the creaser & folder CRF-362 and cross folder AFC-566AKT.

INLINE CUT SHEET PRESS & ROTARY DIE CUTTING SYSTEM

*Collaboration at Konica Minolta booth

This POD card making system produces finished stacks of card applications in a single pass with no operator touchpoints, maximizing efficiency and labor savings. It features a Konica Minolta cut sheet press integrated inline with our rotary die-cutting system, the RD-N4055DM, and our universal sheet buffering module.

INLINE CUT SHEET PRESS & PROCESSING SYSTEM

*Collaboration at FUJIFILM BI booth

This end-to-end system features a FUJIFILM BI cut sheet press integrated inline with our universal sheet buffering module and SmartSlitter sheet processing solution to create applications like tickets and cards in a single pass.

Thank you Beijing 谢谢北京

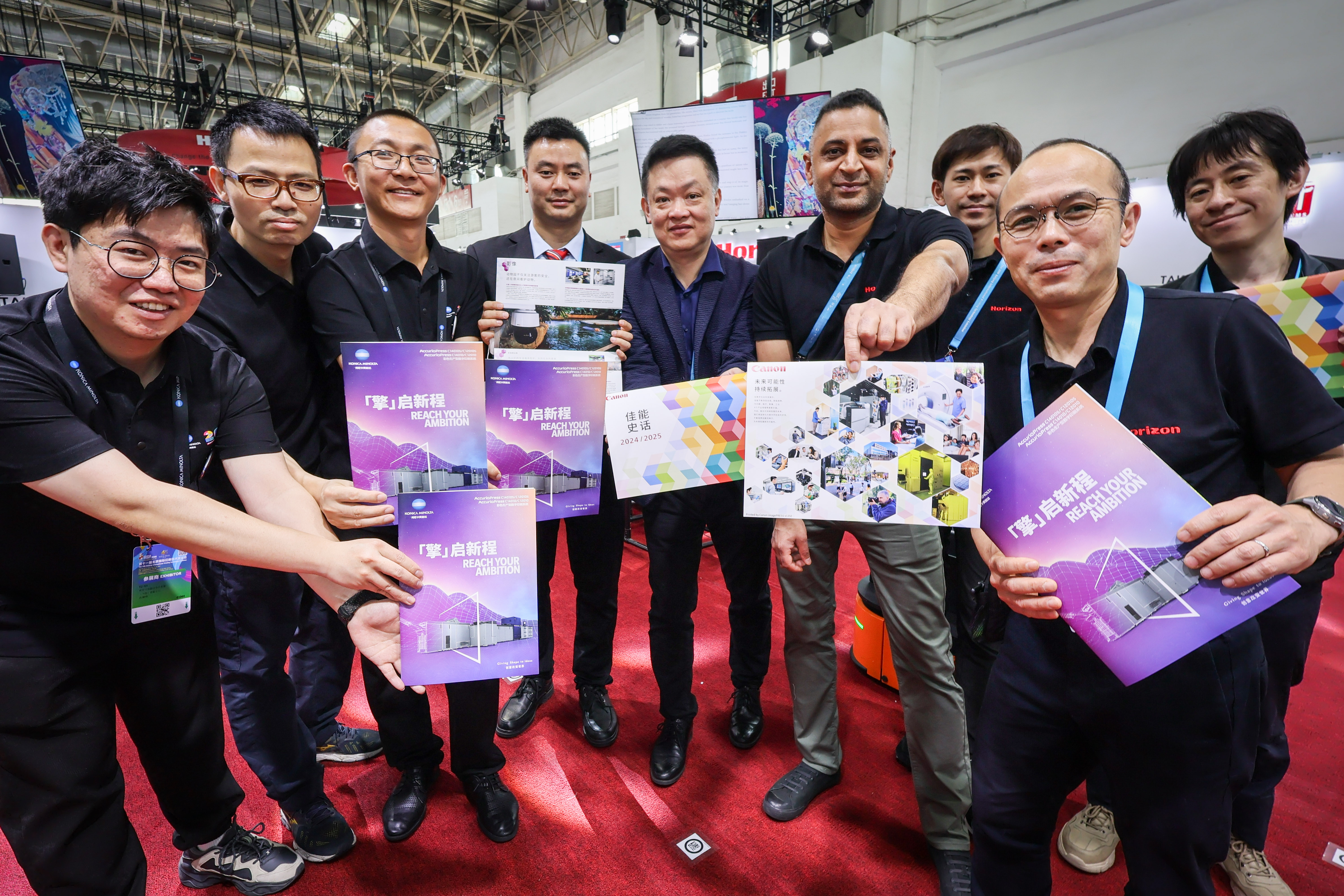

Thank you to everyone who visited our booth, we hope you had a wonderful experience and hope you decide to use Horizon for your finishing needs - or continue to use us if you are a customer already. Another thank you to our industry partners who collaborated with us to offer complete solutions, we look forward to more projects in the future. And last but not least, thank you to all the #TeamHorizon members (especially AFS) who made this event possible.

We look forward to every show we attend for the opportunity to share what we've been working on in person. There is nothing better than reuniting with our global audience.

Until next time… stay happy, stay healthy, and finish first with Horizon!